Discover how to enhance efficiency and productivity in manufacturing facilities by integrating lean and Six Sigma principles into digital signage. Lean and Six Sigma are two methodologies that focus on improving efficiency, reducing waste, and enhancing quality in manufacturing processes.

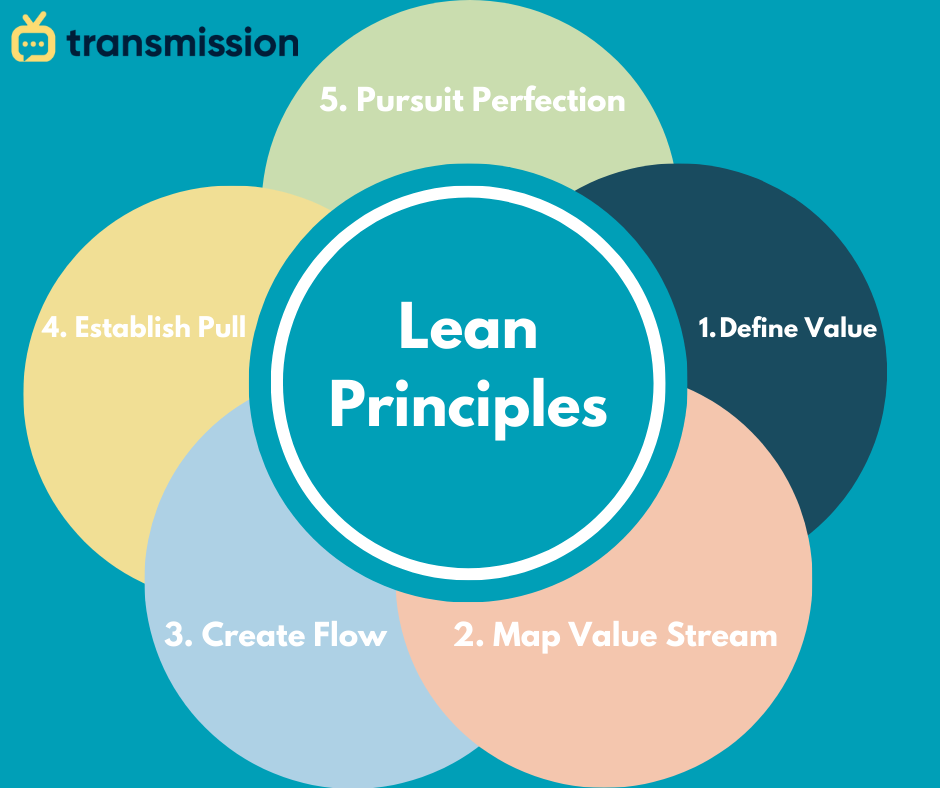

Understanding Lean Principles

Lean principles aim to eliminate any activities or processes that do not add value to the final product. It focuses on eliminating waste, such as overproduction, inventory, unnecessary motion, waiting time, defects, and excess processing.

The five Lean principles provide a framework for creating an efficient and effective organization. Lean allows managers to discover inefficiencies in their facility and deliver better customer value.

Benefits of Implementing Lean Principles in Manufacturing Facilities

Implementing Lean principles in manufacturing facilities offers numerous benefits, including:

- Increased efficiency by eliminating non-value-added activities.

- Streamlined processes and reduced lead times.

- Improved quality through standardized processes and reduced defects.

- Cost reduction by minimizing waste and optimizing resource utilization.

- Enhanced employee engagement and empowerment through involvement in process improvement initiatives.

Integrating Lean Principles with Digital Signage

Integrating digital signage into Lean processes can further optimize efficiency and communication in manufacturing facilities. Key strategies include:

- Visual management: Displaying key performance indicators (KPIs) and real-time data to monitor performance and identify areas for improvement.

- Real-time communication: Using digital signage to disseminate important information and updates to employees, ensuring everyone stays informed and can respond promptly.

- Standard work instructions: Providing standardized work instructions on digital signage to ensure consistency and adherence to best practices.

- Training and skill development: Leveraging digital signage to deliver training materials and interactive content, enabling continuous learning and development.

Understanding Six Sigma Principles

Six Sigma is a data-driven methodology focused on reducing process variation and defects to achieve near-perfect quality levels.

Key elements of Six Sigma include:

- Define: Clearly define project goals, customer requirements, and key metrics for success.

- Measure: Gather data and establish baseline performance metrics to quantify process performance.

- Analyze: Analyze data to identify root causes of defects and process variations.

- Improve: Implementing solutions to address root causes and improve process performance.

- Control: Establishing controls to sustain improvements and prevent regression.

By understanding and implementing Six Sigma principles, manufacturing facilities can optimize their operations, enhance productivity, and deliver high-quality products.

Benefits of Implementing Six Sigma in Manufacturing Facilities

Implementing Six Sigma principles in manufacturing facilities offers several benefits:

- Increased efficiency: Six Sigma helps identify and eliminate non-value-added activities, reducing waste and maximizing productivity.

- Improved quality: Six Sigma improves product quality and customer satisfaction by reducing process variation and defects.

- Cost reduction: Eliminating waste and improving efficiency leads to cost savings by reducing inventory, rework, and other unnecessary expenses.

- Enhanced customer satisfaction: By delivering high-quality products consistently, Six Sigma helps improve customer satisfaction and loyalty.

- Employee engagement: Six Sigma promotes continuous improvement and empowers employees to contribute to process optimization.

Integrating Digital Signage into Six Sigma Processes

Integrating digital signage into Six Sigma can amplify quality control efforts and facilitate data-driven decision-making. Key strategies include:

- Quality control checks: Displaying quality control checklists and statistical process control (SPC) charts on digital signage to monitor process performance and identify deviations.

- Continuous improvement alerts: Setting up alerts on digital signage to notify employees of process deviations or quality issues, enabling prompt corrective actions.

- Feedback mechanisms: Providing employees with the ability to submit feedback and suggestions for process improvement through digital signage, fostering a culture of continuous improvement and employee involvement.

- Gemba walks: Facilitating Gemba walks by displaying schedules, checklists, and improvement opportunities on digital signage, ensuring structured observations and actionable insights.

How to Implement Six Sigma and Lean Principles into Digital Signage

1. Visual management: Digital signage can be used to display key performance indicators (KPIs), production targets, and real-time data on performance metrics. Employees can quickly identify and address deviations from desired standards by offering a visual snapshot of operations.

2. Real-time communication: Digital signage provides a platform for real-time communication of important information, such as safety alerts, production updates, and process changes. This ensures that all employees are informed and can respond promptly.

3. Standard work instructions: Digital signage can be utilized to display standard work instructions, reducing the need for paper-based instructions and minimizing errors. This improves consistency and compliance with standardized processes.

4. Training and skill development: Digital signage can be used to deliver training materials, videos, and interactive content to enhance employee skills and knowledge. This enables continuous learning and development within the organization.

By integrating digital signage into Lean and Six Sigma processes, manufacturing facilities can improve communication, visibility, and adherence to standardized processes, increasing efficiency and productivity.

Evaluating Performance and Sustaining Progress

To evaluate the performance and sustain progress in implementing Lean and Six Sigma principles with digital signage, consider the following:

1. Key performance indicators (KPIs): Define and track KPIs related to efficiency, quality, cost, and customer satisfaction. Regularly analyze and review the data to identify areas for improvement and monitor progress.

2. Continuous improvement culture: Foster a culture of continuous improvement by encouraging employee involvement and feedback. Implement mechanisms for collecting suggestions and ideas for process optimization. Pro Tip: Use your digital signage to promote employee feedback surveys!

3. Training and development: Provide ongoing training and development opportunities to ensure employees have the necessary skills and knowledge to effectively utilize digital signage and apply Lean and Six Sigma principles.

4. Review and feedback mechanisms: Establish regular review meetings and feedback sessions to assess the effectiveness of digital signage and identify any challenges or areas for improvement.

5. Documentation and standardization: Document the processes and procedures related to digital signage implementation and Lean and Six Sigma principles. Standardize the best practices and share them across the organization.

By evaluating performance and sustaining progress, manufacturing facilities can continuously improve their operations, leverage the benefits of digital signage, and achieve long-term success.